OPTIMERIAL

Our Vision

Our vision is to redefine the boundaries of what is technologically possible and create a future in which materials go far beyond their current capabilities. Building on proven technologies of today, we continuously drive innovation to develop an entirely new class of materials:

metamaterials.

These high-precision materials are characterized by properties that are rare or non-existent in nature. They offer us the opportunity to specifically control physical properties and adapt them to specific requirements. In our case, these are structures with a finely tuned resonance spectrum: they can have targeted frequency gaps or provide frequencies densely packed in a customer-specific interval.

What's special about it? These innovative properties are achieved without significantly changing the external shape or weight of the components - a decisive advantage, because these parameters are often determined by the function and area of application of a product.

Our mission is to harness these groundbreaking technologies to meet the demands of tomorrow - be it in communications technology, medical technology, aerospace or other demanding application areas. Through our work, we build a bridge between scientific excellence and industrial feasibility to deliver solutions that improve our world in a lasting way.

What are Metamaterials?

Metamaterials are engineered materials designed to exhibit properties not found in natural substances, often by assembling multiple homogeneous materials with different physical properties. One such property that can be controlled in metamaterials is the density of the constituents, which can be tailored to produce a desired spectrum of vibrations or acoustic and elastic responses.

In the context of structural or mechanical metamaterials, these materials are often made up of different components, each with a different density. Varying the density across the material allows the creation of a composite structure where the overall behavior - such as resonance, vibration frequencies, and wave propagation - can be tailored to specific requirements. This manipulation of densities can be used to tune the frequency response of the material, allowing the material to either absorb, block, or amplify certain frequencies depending on the application.

The design of such metamaterials typically involves arranging the different materials in such a way that their individual properties are combined to achieve a desired macroscopic behavior. For example, in a mechanical metamaterial designed to control vibrations, regions of high-density material can be positioned to shift or modify the natural frequencies of the vibration, while regions of lower-density materials can be used to influence the damping or propagation of sound and waves. The result is a material with a complex frequency spectrum that can be specifically engineered to meet specific requirements, such as vibration isolation, noise reduction, or the generation of novel wave phenomena.

This approach enables the creation of materials that behave in highly controlled and predictable ways. For example, by adjusting the arrangement and density of materials, it is possible to design a metamaterial with a bandgap for specific frequencies, essentially preventing those frequencies from propagating through the material - much like photonic crystals control light. Similarly, the design could allow a material to resonate at a specific frequency for applications in sensors, energy harvesting, or even acoustic devices.

Metamaterials with different densities also open up new possibilities for advanced engineering applications, where the ability to tailor the properties of the material at a microscopic level leads to innovative solutions for noise reduction, improved mechanical performance, and even novel materials for aerospace, automotive, and medical devices. As research in this field advances, the design and application of such materials is likely to revolutionize many industries by enabling previously unattainable control over the frequency spectrum to which these materials respond.

Types of Metamaterials

The term metamaterial describes a very large class of new materials that have physical properties that do not exist in nature or only very rarely. These physical properties can be mechanical, electrical, thermal or optical in nature. It is always about arranging several homogeneous materials with known properties in a very specific configuration so that the resulting bodies have the desired properties. The "classic" example of a mechanical metamaterial is an elongated body with negative transverse contraction. This body would not constrict in the middle when pulled apart, as is known from natural materials, but would, on the contrary, expand transversely to the direction of tension.

The acoustic metamaterials that we are dealing with are also mechanical metamaterials. We build gaps into the resonance spectrum of a body or condense the spectrum of resonance frequencies in a desired interval. We also shift the entire sound spectrum to zero to make it more flexible or to the highest possible values to stiffen the component.

Below we describe in detail which materials these are.

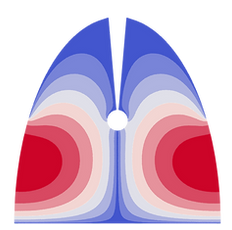

Such bodies are almost 2-dimensional and have only a small extension in the vertical direction. These shapes are often referred to as quasi-2D materials. They are uniform along this axis in terms of material density and show different material properties in the horizontal plane, as shown in the image below. Materials with different densities are arranged in a way that the entire body has a desired spectral property. In this case, the spectrum is shifted to zero to make the body as flexible as possible. The hole inside exists for technical reasons. The body is not fixed at this inner edge and can vibrate freely. If the membrane at the inner edge were also fixed, it would result in a different distribution of the optimal density. The size and geometry of these bodies can be designed very flexibly, with any number of edge parts as well as holes or slits.

Metamaterials of this type are still difficult to produce en masse, especially at the interfaces between the homogeneous materials.

Example of the density distribution in a square body fixed on the outside with a hole in the middle.

Example of density distribution in a body with complex geometry.